For a good cold room, to use the right way to finish the installation is very important, cause the cold storage room requires excellent sealing performance--Once the sealing performance cannot be guaranteed, It may greatly increase energy loss and spoilage of goods.

The cold storage sandwich panels—it is usually composed with 2-layer pre-painted steel sheet with polyurethane(pu)/polyisocyanurate(pir) insulated core material. As is known to all, the pu/pir is the best thermal insulation building material—so it gives the best cold storage performance with B1 fireproof at the same time.

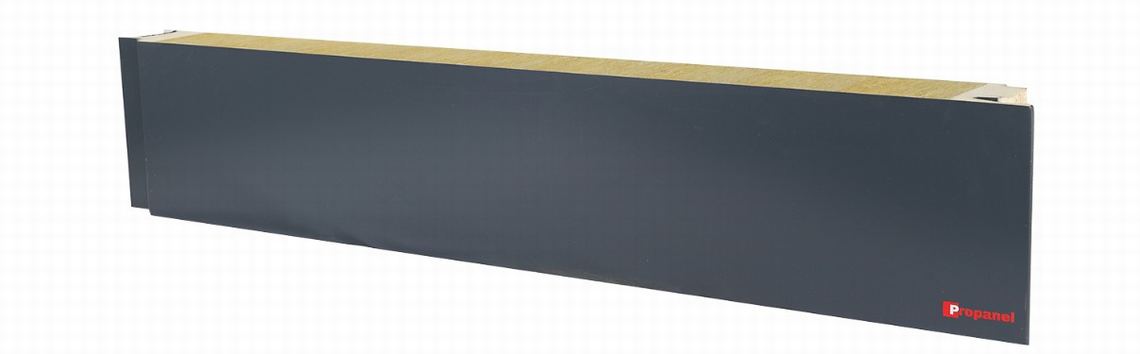

First of all, ensuring that the quality of the cold storage composite panels is good is the top priority. Propanel, just focus on supplying the pu/pir cold room sandwich panels, give customers the best solution also best price at the same time.

Secondly, ground site preparation and inspection must be done before installation. If the foundation is uneven - the panels won't line up properly - this can cause gaps to appear, ultimately allowing cold air to escape.

Thirdly, node connections are easily handled improperly. Nodes such as column edge connections, wall corner connections, and suspended ceiling points require professional personnel to connect them according to professional instructions. Improper operation can cause cold bridge phenomenon, finally leading to energy loss and damage to the cold storage panels.