In metal roofing installation, panel overlap is a crucial step determining the success or failure of the system. This seemingly simple operation is often misunderstood and simplified. Many people fail to realize that proper overlap is the core guarantee of roof waterproofing. Any improper operation, such as insufficient overlap, poor sealing, or misaligned fasteners, can lead to leaks, wind damage, and insulation failure. This guide will explain the key points of proper overlap, helping you ensure the long-term reliability of your roof from the source.

Why Metal Roof Overlap Matters?

Metal roof panels require overlap primarily due to two basic needs:

☆The limited size of individual panels necessitates horizontal and vertical splicing to cover the entire roof;

☆The overlap structure provides a crucial waterproof barrier for the joints.

By stacking the upper panel on top of the lower one, rainwater is guided downwards, preventing it from seeping into the joints, effectively preventing leaks and protecting the building structure. Furthermore, this overlap method enhances the overall wind resistance of the roof and contributes to a neat and aesthetically pleasing appearance.

What are the methods for overlapping steel roofs?

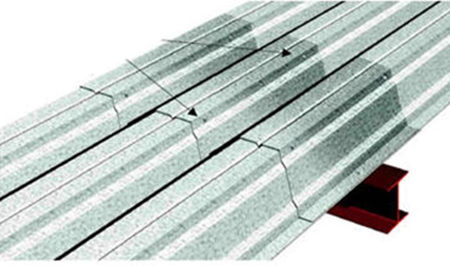

The installation of steel roof panels mainly involves two basic types of overlap: side overlap and end overlap. Side overlaps address the side-by-side connection of roof panels along the width of the roof, while end overlaps address the issue of panel extension along the roof slope. These two methods together constitute the key to roof waterproofing and structural stability.

|

|

|

|

Side Overlaps: Ensuring Side-by-Side Connections |

End Overlaps: Extending the Length |

|

Side overlaps refer to the horizontal splicing of panels along the roof. The overlap amount depends on the corrugation or rib profile of the panel. For example, common corrugated panels require at least one overlap at a trough, while box-type panels typically require an overlap at a rib. Under normal conditions, this overlap is sufficient, but in areas with strong winds, the overlap can be increased to enhance overall wind and rain resistance.

|

When the roof length exceeds that of a single panel, end overlaps are required, where the upper panel is stacked on top of the lower one along the slope. Generally, a minimum overlap length of 150 mm is recommended for roofs with a slope greater than 10°. For gentler roof slopes, this should be extended to 200 mm or more, supplemented with sealing tape or sealant to ensure durable waterproofing of the longitudinal joints.

|

The overlap length of metal roofing panels needs to be determined based on a combination of factors, including the roof slope, panel profile, and local climate conditions.

|

Roof Slope |

Steeper roofs facilitate drainage, allowing for shorter overlaps. Gently sloped roofs require longer overlaps to prevent water accumulation. |

|

Panel Profile |

The depth and design of the panel profile affect drainage efficiency. |

|

Weather Conditions |

In areas with strong winds, heavy rain, or blizzards, it is best to increase the overlap length to reinforce the joints. |