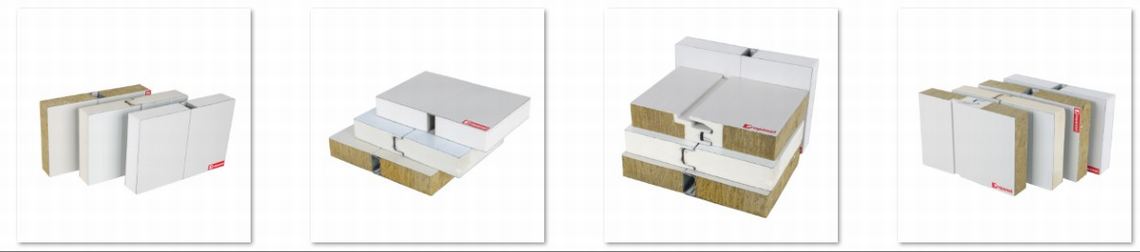

Discover PROPANEL Sandwich Metal Roofing Systems

PROPANEL sandwich metal roofing systems are a good choice for Large Projects. Made with a strong metal exterior and an insulating core, these panels resist extreme weather like heavy rain or strong winds. Whether it’s a warehouse or a factory project, PROPANEL gives a long-lasting solution that you can wait for.

Why Choose Sandwich Panels for Your Roof?

Sandwich panels from PROPANEL bring more than just strength. The design has better heat insulation, making buildings super energy-efficient. This means lower heating and cooling bills for your building. The insulation also cuts down noise, perfect for busy industrial spaces. With PROPANEL, you get a roof that saves money and keeps things comfortable inside.

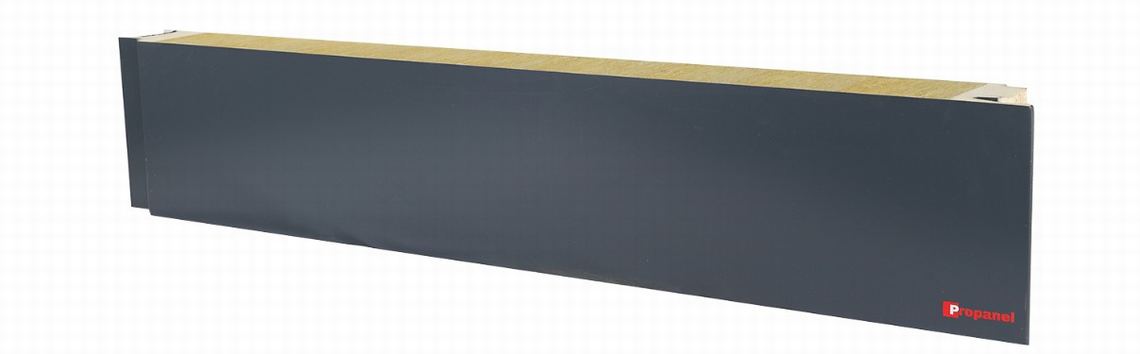

Easy Installation with PROPANEL

One big advantage of PROPANEL sandwich metal roofing is how simple it is to install. The lightweight panels fit together quickly, saving time on big projects. No need for professional tools or long times—contractors will love how fast they can get the job done. PROPANEL’s prefab building material system means your roof is up and ready without any trouble.

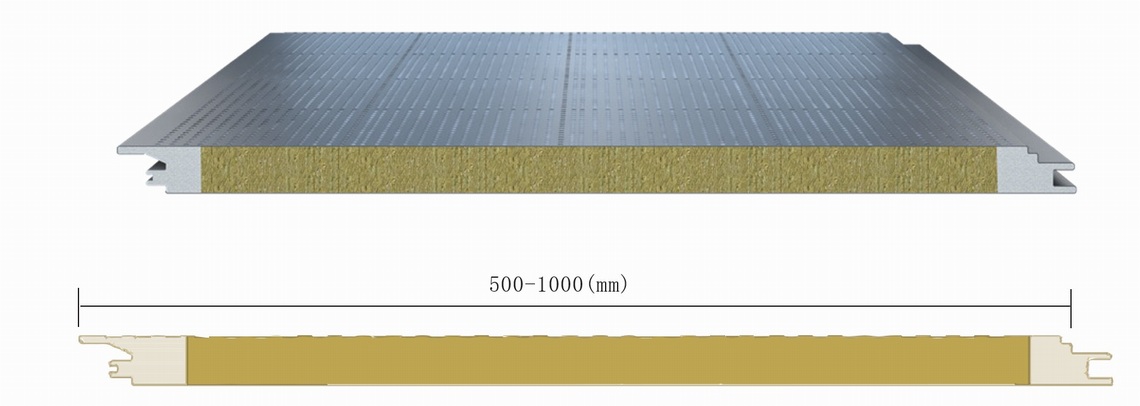

PROPANEL: Built for Efficiency and Strength

What makes PROPANEL so good for the building? It’s the combination of insulation and easy installation (prefabricated steel building materials). These sandwich roof panels keep buildings cooler in summer and warmer in winter, giving strong against for extreme weather. From storage rooms to large workshops, PROPANEL offers a reliable, low-maintenance roofing option that both better performance and value.