Sandwich panels can be customized for design and size to meet exact project specs for sure.

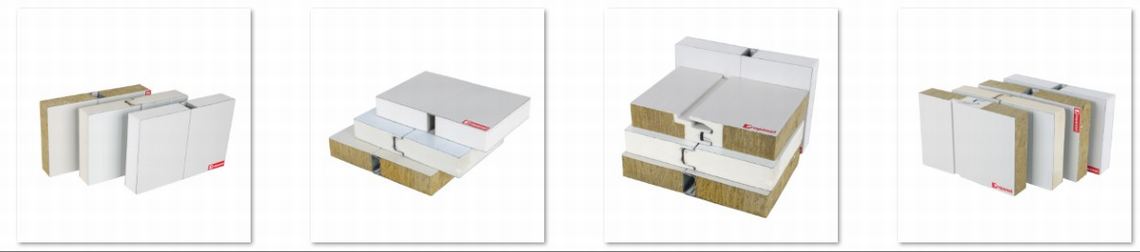

Common sandwich panel’s thickness varies from 30mm to 300mm, and lengths from 400mm to 12000mm. Factories use automated cutting for precision during production. Quality checks test thickness fittings and core density to ensure standards.

While the core materials of sandwich panel also allow custom options: EPS for light weight, rock wool/glass wool for sound control and fire safety, and PU/PIR for better insulation. As professional rock wool panel china manufacturer as well as china cold storage panel manufacturer—PROPANEL, is engaged to give the best products to customer.

The metal surface layers include steel sheet, aluminum plate, or stainless-steel sheet... Inspections verify material bonds and fire ratings with lab tests.

The paint types of metal surface offer customization: PE for basic protection, HDP for higher durability, SMP for higher weather resistance, and PVDF for longer color life. Panels go through roller coating in production for even finish. This step follows strict color matching. Final quality detection uses visual and machine scans to confirm paint adhesion and thickness.

Special shapes sandwich panels like triangles or circles satisfy unique needs. Molds shape panels during manufacturing for custom fits. These handles curved or angled designs. Production ends with load tests and seal checks to confirm strength. Such special quality control ensures panels perform in all kinds of buildings’ roofs or walls.